INNO Instrument

The industry standard for core alignment

splicers: View 5X

INNO Instrument’s View 5X is a core alignment splicer that’s a pleasure to work with: fast, precise and efficient. No wonder the View 5X is the benchmark for working comfort and productivity.

A 520 × magnification combined with the high-resolution 5-inch color LCD touchscreen allows extremely detailed control.

The user-friendly interface is intuitive, and the speed of work cycles is unrivalled: 4 seconds splice time and 9 seconds heating time in fast mode. And thanks to the powerful battery, up to 300 cycles (standard modes) are possible.

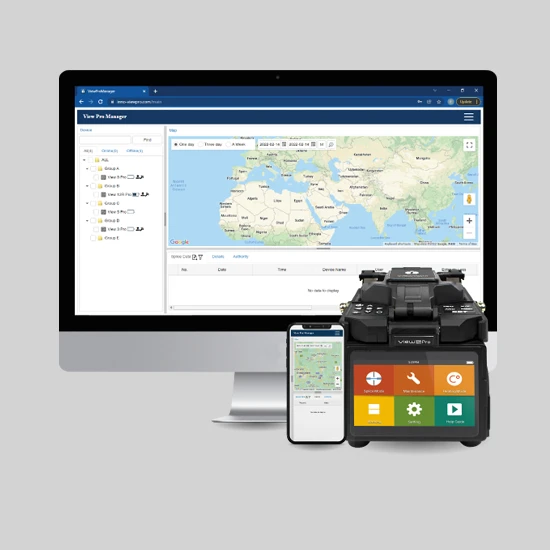

A decisive added value of INNO splicers is the integration into the free View Pro Cloud Management System, which enables an entirely new. level of remote management. The web-based application enables onsite staff and back-office management to optimize workflows, generate comprehensive evaluations and much more.

Product sheet View 5X

Technical specifications

Model

View 5X

Number of fiber

Single

Alignment method

Core alignment

Applicable fibers

SM (ITU-T G.652 & G.657) / MM (ITU-T G.651) / DS (ITU-T G.653) / NZDS (ITU-T G.655)

Coating diameter

100 μm to 3 mm

Cleaved length

5 to 16 mm

Cladding diameter

80 to 150 μm

Splice programs

Maximal 128 modes

Heating programs

Maximal 32 modes

Typical splice loss

SM: 0.01 dB / MM: 0.01 dB / DS: 0.03 dB / NZDS: 0.03 dB / G.657: 0.01 dB

Splice time (typical) *

Quick mode: 4 seconds / SM mode 5 seconds / Auto mode: 7 seconds

Heating time

Quick mode: 9 seconds / Average: 13 seconds

Protection sleeve length

20 to 60 mm

Display

5″ Color LCD display, Full Touch Screen

Fiber view

X, Y, XY, X/Y

Fiber display (magnification)

× 360 and × 520

Return loss

› 60 dB

Data storage

Last 20,000 (values) or 10,000 (images) results

Pull test

1,96–2,25 N

Operation

Button / Touch screen

Lighting

White LED

Power supply

AC input 100 to 240 V / DC input 9 to 19 V

Battery *

Capacity: 5,200 mAh / Typical operation cycles: 300 cycles (splicing and heating)

Electrode life span

6,000 arc discharges

Data output

Cloud (View Pro Manager) and USB-C

Operating conditions *

Operating altitude: 0 to 5,000 m above sea level / 0 to 95 % relative humidity (non-dew) / −10 to 50 °C / Max. wind 15 m/s

Storage conditions

0 to 95 % relative humidity (non-dew) / −40 to 80 °C

Tests

Water resistance (IPx2): Rain resistance: 10 mm/h for 10 minutes

Shock resistance: 76 cm for bottom surface drop

Dust resistance (IP5X): Exposure to dust: 0.1 to 500 μm diameter aluminium silicate

Dimensions in mm (Height × Width × Depth)

151 × 149 × 177

Weight

2.35 kg

View Pro Manager

Another key added value of the View 5X is its integration with the free View Pro Cloud Management System, which offers a whole new level of remote management.

The highlights:

All functions are controlled or accessed from the dashboard on the PC or mobile phone connected to the INNO iCloud server. The View 5X in turn communicates with the server via a 4G / 5G cellular network. All it needs is a low-cost IoT SIM card and the splicer is on the web. And all the information is available as quickly as possible and always up to date.

Scope of delivery

Tools, consumables and accessories

In addition to the splicer, various tools are required to properly prepare the fibers. If you are not yet equipped here, we will of course be happy to help. Whether it’s the right stripper, loose tube cutter, cleaning fluid and cloths or a crimping press: you can get everything from us. And we are at your side with advice and action. Talk to us or get an initial overview online.